Zatsopano zatsopano za IC stock Electronic Components Ic Chip Support BOM Service DS90UB953TRHBRQ1

Makhalidwe a Zamalonda

| TYPE | DESCRIPTION |

| Gulu | Magawo Ophatikizana (ICs) |

| Mfr | Texas Instruments |

| Mndandanda | Magalimoto, AEC-Q100 |

| Phukusi | Tape & Reel (TR) Dulani Tepi (CT) Digi-Reel® |

| SPQ | 3000T&R |

| Mkhalidwe wa Zamalonda | Yogwira |

| Ntchito | Seriizer |

| Mtengo wa Data | 4.16Gbps |

| Mtundu Wolowetsa | CSI-2, MIPI |

| Mtundu Wotulutsa | FPD-Link III, LVDS |

| Nambala ya Zolowetsa | 1 |

| Chiwerengero cha Zotuluka | 1 |

| Voltage - Zopereka | 1.71V ~ 1.89V |

| Kutentha kwa Ntchito | -40°C ~ 105°C |

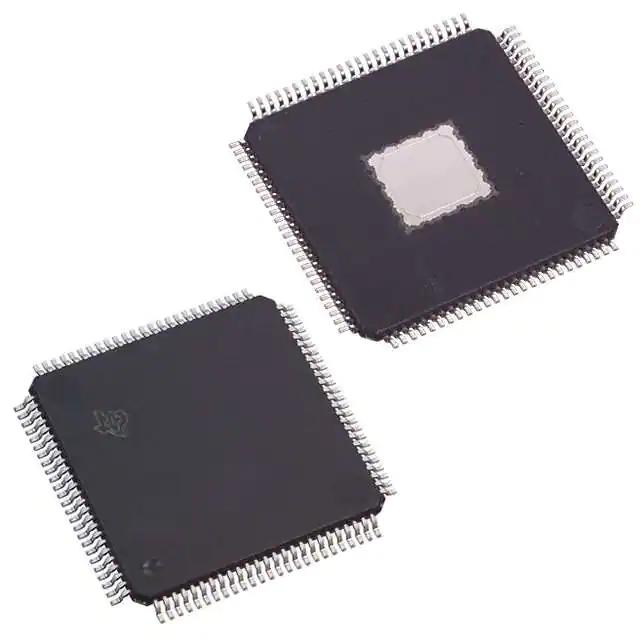

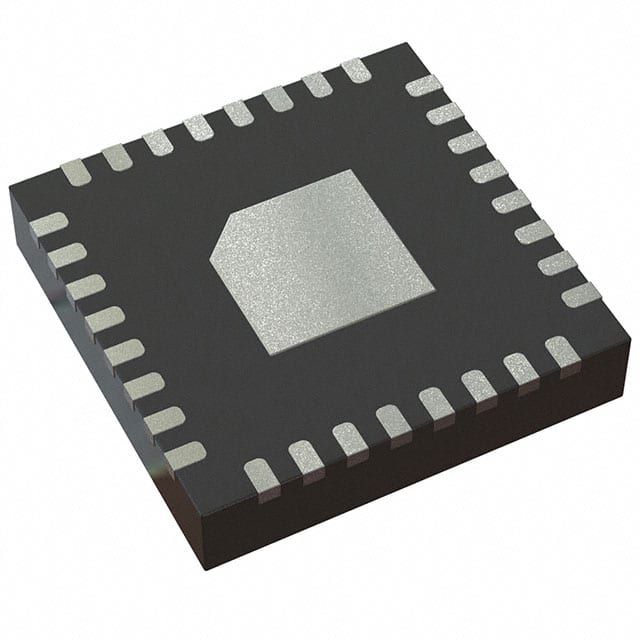

| Mtundu Wokwera | Surface Mount, Mphepete mwa Wettable |

| Phukusi / Mlandu | 32-VFQFN Yowonekera Pad |

| Phukusi la chipangizo cha Supplier | 32-VQFN (5x5) |

| Nambala Yoyambira Yogulitsa | Chithunzi cha DS90UB953 |

1. Chifukwa silicon kwa tchipisi?Kodi pali zida zomwe zingalowe m'malo mwake mtsogolo?

Zopangira tchipisi ndi zowonda, zomwe zimapangidwa ndi silicon.Pali malingaliro olakwika akuti "mchenga ukhoza kugwiritsidwa ntchito kupanga tchipisi", koma sizili choncho.Chigawo chachikulu chamchenga ndi silicon dioxide, ndipo chigawo chachikulu chagalasi ndi zowotcha ndi silicon dioxide.Kusiyana kwake, komabe, ndikuti galasi ndi silicon ya polycrystalline, ndipo mchenga wotentha pamtunda wotentha umatulutsa silicon ya polycrystalline.Komano, zowotcherera ndi silicon monocrystalline, ndipo ngati zimapangidwa kuchokera ku mchenga ziyenera kusinthidwanso kuchokera ku polycrystalline silicon kupita ku silicon monocrystalline.

Kodi silicon ndi chiyani ndipo chifukwa chiyani ingagwiritsidwe ntchito kupanga tchipisi, tiwulula izi m'nkhaniyi imodzi ndi imodzi.

Chinthu choyamba chimene tiyenera kumvetsetsa ndi chakuti zinthu za silicon sizidumphira mwachindunji ku sitepe ya chip, silicon imayengedwa kuchokera ku mchenga wa quartz kuchokera ku element silicon, silicon element proton nambala kuposa aluminium element aluminium imodzi, kuposa phosphorous element imodzi yocheperapo. , sizinthu zokhazokha za zipangizo zamakono zamakono zamakono komanso anthu omwe akufunafuna zamoyo zam'mlengalenga chimodzi mwa zinthu zofunika kwambiri zomwe zingatheke.Nthawi zambiri, silicon ikatsukidwa ndikuyengedwa (99.999%), imatha kupangidwa kukhala zowotcha za silicon, zomwe zimadulidwa kukhala zopyapyala.Kuchepa kwa mtanda kumapangitsa kuti mtengo wopangira chip ukhale wotsika, koma m'pamenenso zofunika pakupanga chip zimakwera.

Njira zitatu zofunika pakusinthira silicon kukhala zowotcha

Mwachindunji, kusinthika kwa silicon kukhala zowotcha zitha kugawidwa m'magawo atatu: kuyengetsa ndi kuyeretsa kwa silicon, kukula kwa silicon imodzi ya crystal, ndi kupanga mkate.

Mwachilengedwe, silicon nthawi zambiri imapezeka ngati silicate kapena silicon dioxide mumchenga ndi miyala.Zopangirazo zimayikidwa mu ng'anjo yamagetsi yamagetsi pa 2000 ° C ndi pamaso pa gwero la mpweya, ndipo kutentha kwakukulu kumagwiritsidwa ntchito pochita silicon dioxide ndi carbon (SiO2 + 2C = Si + 2CO) kuti mupeze chitsulo chachitsulo (SiO2 + 2C = Si + 2CO) chiyero pafupifupi 98%).Komabe, chiyero ichi sichikwanira kukonzekera zipangizo zamagetsi, choncho ziyenera kuyeretsedwanso.The wosweka metallurgical kalasi silikoni ndi chlorinated ndi mpweya wa haidrojeni kolorayidi kupanga madzi silane, amene ndiye distilled ndi mankhwala kuchepetsedwa ndi ndondomeko kuti amapereka mkulu chiyero polysilicon ndi chiyero cha 99.9999999999% monga pakompyuta kalasi silicon.

Ndiye mumapeza bwanji silicon ya monocrystalline kuchokera ku silicon ya polycrystalline?Njira yodziwika kwambiri ndiyo kukoka kwachindunji, kumene polysilicon imayikidwa mu quartz crucible ndi kutenthedwa ndi kutentha kwa 1400 ° C yomwe imagwira pamphepete, yomwe imapanga polysilicon kusungunuka.Zachidziwikire, izi zimatsogozedwa ndikuviika kristalo wambewu m'menemo ndikukhala ndi ndodo yojambulira kunyamula kristalo wa mbewu mbali ina kwinaku pang'onopang'ono ndikuyikokera mmwamba kuchokera ku silicon kusungunuka.Silicon yosungunuka ya polycrystalline imamatira pansi pa kristalo wa mbewu ndikukula m'mwamba molunjika ku kristalo wa kristalo wa mbewu, yomwe ikatulutsidwa ndi kuzizira imakula kukhala kristalo imodzi yokhala ndi mawonekedwe ofanana ndi amkati mwa kristalo.Pomaliza, zowotcha zamtundu umodzi wa kristalo zimagwetsedwa, kudulidwa, kugwa, kusinthidwa, ndikupukutidwa kuti apange zowotcha zofunika kwambiri.

Kutengera kukula kwake, zowotcha za silicon zitha kugawidwa ngati 6 ", 8", 12 "ndi 18".Kukula kwa mkate wophatikizika, m'pamenenso tchipisi tambiri timadulidwe pa kabati kakang'ono, ndipo mtengo wake umakhala wotsika kwambiri.

2.Three masitepe zofunika pa kusintha kwa silicon mu zopyapyala

Mwachindunji, kusinthika kwa silicon kukhala zowotcha zitha kugawidwa m'magawo atatu: kuyengetsa ndi kuyeretsa kwa silicon, kukula kwa silicon imodzi ya crystal, ndi kupanga mkate.

Mwachilengedwe, silicon nthawi zambiri imapezeka ngati silicate kapena silicon dioxide mumchenga ndi miyala.Zopangirazo zimayikidwa mu ng'anjo yamagetsi yamagetsi pa 2000 ° C ndi pamaso pa gwero la mpweya, ndipo kutentha kwakukulu kumagwiritsidwa ntchito pochita silicon dioxide ndi carbon (SiO2 + 2C = Si + 2CO) kuti mupeze chitsulo chachitsulo (SiO2 + 2C = Si + 2CO) chiyero pafupifupi 98%).Komabe, chiyero ichi sichikwanira kukonzekera zipangizo zamagetsi, choncho ziyenera kuyeretsedwanso.The wosweka metallurgical kalasi silikoni ndi chlorinated ndi mpweya wa haidrojeni kolorayidi kupanga madzi silane, amene ndiye distilled ndi mankhwala kuchepetsedwa ndi ndondomeko kuti amapereka mkulu chiyero polysilicon ndi chiyero cha 99.9999999999% monga pakompyuta kalasi silicon.

Ndiye mumapeza bwanji silicon ya monocrystalline kuchokera ku silicon ya polycrystalline?Njira yodziwika kwambiri ndiyo kukoka kwachindunji, kumene polysilicon imayikidwa mu quartz crucible ndi kutenthedwa ndi kutentha kwa 1400 ° C yomwe imagwira pamphepete, yomwe imapanga polysilicon kusungunuka.Zachidziwikire, izi zimatsogozedwa ndikuviika kristalo wambewu m'menemo ndikukhala ndi ndodo yojambulira kunyamula kristalo wa mbewu mbali ina kwinaku pang'onopang'ono ndikuyikokera mmwamba kuchokera ku silicon kusungunuka.Silicon yosungunuka ya polycrystalline imamatira pansi pa kristalo wa mbewu ndikukula m'mwamba molunjika ku kristalo wa kristalo wa mbewu, yomwe ikatulutsidwa ndi kuzizira imakula kukhala kristalo imodzi yokhala ndi mawonekedwe ofanana ndi amkati mwa kristalo.Pomaliza, zowotcha zamtundu umodzi wa kristalo zimagwetsedwa, kudulidwa, kugwa, kusinthidwa, ndikupukutidwa kuti apange zowotcha zofunika kwambiri.

Kutengera kukula kwake, zowotcha za silicon zitha kugawidwa ngati 6 ", 8", 12 "ndi 18".Kukula kwa mkate wophatikizika, m'pamenenso tchipisi tambiri timadulidwe pa kabati kakang'ono, ndipo mtengo wake umakhala wotsika kwambiri.

Chifukwa chiyani silicon ndiye chinthu choyenera kwambiri popangira tchipisi?

Mwachidziwitso, ma semiconductors onse amatha kugwiritsidwa ntchito ngati zida za chip, koma zifukwa zazikulu zomwe silicon ndiye chinthu choyenera kwambiri chopangira tchipisi ndi motere.

1, malinga ndi kusanja kwa zinthu zapadziko lapansi, kuti: mpweya> silicon> aluminiyamu> chitsulo> calcium> sodium> potaziyamu ...... atha kuwona kuti silicon ili pachiwiri, zomwe zili ndi zazikulu, zomwe zimalolanso chip kukhala ndi katundu pafupifupi osatha wa zipangizo.

2, silicon element chemical properties ndi zinthu zakuthupi ndizokhazikika kwambiri, transistor yoyambirira ndiyo kugwiritsa ntchito zida za semiconductor germanium kupanga, koma chifukwa kutentha kumaposa 75 ℃, kusinthika kudzakhala kusintha kwakukulu, kopangidwa kukhala PN mphambano pambuyo pake. kutayikira kwa germanium tsopano kuposa silicon, kotero kusankha kwa silicon element ngati chip mfundo ndikoyenera;

3, ukadaulo wa silicon element purification ndi wokhwima, komanso wotsika mtengo, masiku ano kuyeretsedwa kwa silicon kumatha kufika 99.9999999999%.

4, zinthu za silicon zokha ndizopanda poizoni komanso zopanda vuto, zomwe ndi chimodzi mwazifukwa zofunika zomwe zimasankhidwa ngati zinthu zopangira tchipisi.

.png)